A bustling factory floor, filled with the hum of machines and the rustle of paper. Amidst the flurry of activity, a team of dedicated craftsmen and women are hard at work, transforming simple sheets of paper into something extraordinary – zipper shipping boxes. It’s a fascinating process, one that starts with a vision and ends with a product that’s both functional and stylish. Let’s take a closer look at how a paper gift box factory brings innovative zipper shipping boxes to life.

The Art of Paper Transformation

The journey of a paper gift box begins with the raw material – paper. This isn’t just any paper, it’s a specially selected material known for its durability and aesthetic appeal. The paper is sourced from sustainable forests, ensuring that the production process is eco-friendly. Once the paper arrives at the factory, it undergoes a series of treatments to prepare it for the transformation into a zipper shipping box.

Innovation in Design

Design is at the heart of what makes a zipper shipping box stand out. A paper gift box factory invests heavily in research and development to create designs that are not only practical but also visually appealing. The designers at the factory work tirelessly to come up with innovative patterns and structures that cater to a wide range of clients, from e-commerce businesses to individuals looking for unique packaging solutions.

The Role of Technology

In the world of paper gift box manufacturing, technology plays a crucial role. Advanced machinery is used to cut, fold, and glue the paper into the desired shape. The factory employs state-of-the-art equipment that allows for precision and efficiency in the production process. This technology also enables the factory to create complex designs that would be impossible to achieve by hand.

Sustainability and Eco-Friendliness

Sustainability is a key focus for any modern paper gift box factory. The factory takes pride in its commitment to reducing environmental impact. This includes using recycled paper where possible, minimizing waste during production, and ensuring that the end product is recyclable. The factory also invests in energy-efficient machinery and practices to reduce its carbon footprint.

Quality Control and Assurance

Every zipper shipping box that leaves the factory must meet strict quality standards. The factory has a dedicated quality control team that inspects each box for any defects or inconsistencies. This rigorous process ensures that only the highest quality products reach the customers. The factory also implements feedback mechanisms to continuously improve its products based on customer input.

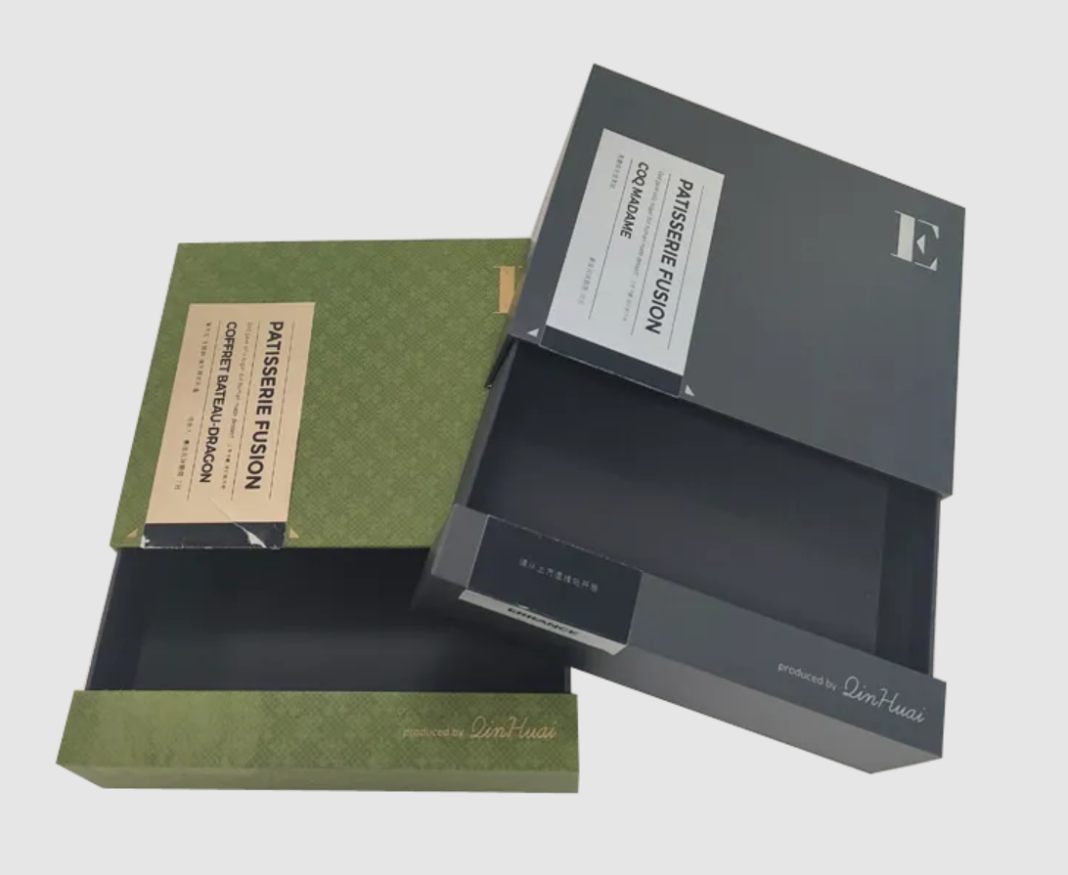

Customization and Personalization

One of the most exciting aspects of working with a paper gift box factory is the ability to customize and personalize the zipper shipping boxes. Clients can choose from a variety of colors, patterns, and even add their own logos or branding. This level of personalization allows businesses to create packaging that reflects their brand identity and stands out on the shelf.

The Packaging Process

Once the design and customization are finalized, the packaging process begins. The paper is carefully cut and folded into the shape of a box. A special zipper mechanism is added to the top of the box, allowing for easy opening and closing. This feature is not only convenient for the end user but also adds a touch of sophistication to the packaging.

The Journey to the Customer

After the boxes are produced and packaged, they make their way to the customer. Whether it’s a small batch for a local business or a large shipment for an international company, the paper gift box factory ensures that each order is delivered on time and in perfect condition. The factory’s logistics team works closely with shipping partners to ensure that the boxes reach their destination safely and efficiently.

The Impact of Paper Gift Boxes

The use of paper gift boxes, especially those with zipper shipping features, has a significant impact on the packaging industry. They offer a sustainable and stylish alternative to traditional plastic packaging. Not only do they look good, but they also provide a practical solution for businesses looking to reduce their environmental footprint while maintaining a professional image.

The Future of Paper Gift Box Factories

As the demand for eco-friendly packaging solutions grows, paper gift box factories are poised to play a significant role in shaping the future of the industry. With continued innovation in design and technology, these factories are well-equipped to meet the needs of a changing market. They are not just producing boxes, they are creating a sustainable future for packaging.

In conclusion, the process of creating innovative zipper shipping boxes at a paper gift box factory is a testament to the power of creativity, technology, and sustainability. From the initial design to the final product, every step is carefully planned and executed to ensure that the end result is nothing short of exceptional. Whether you’re a business looking for a unique packaging solution or a consumer appreciating the eco-friendly choice, paper gift boxes with zipper shipping features are a win-win for everyone involved.